Drying Shakers

Complete Solids Control offers premium linear motion drying shakers to ensure a fast and efficient turnaround time on your fluid recovery process. Our linear motion drying shakers are multi-functional drilling fluid cleaners built to handle varying drilling fluid viscosities and remove solids from drilling fluid.

Completes Solids Control and waste management services is THE Complete solution of closed-loop, zero discharge systems. Our goal is to reduce liquid waste haul off. Our linear motion drying shaker coupled with advanced fine screening plays a significant role in the Complete closed loop package. We can install double or triple shaker systems as needed.

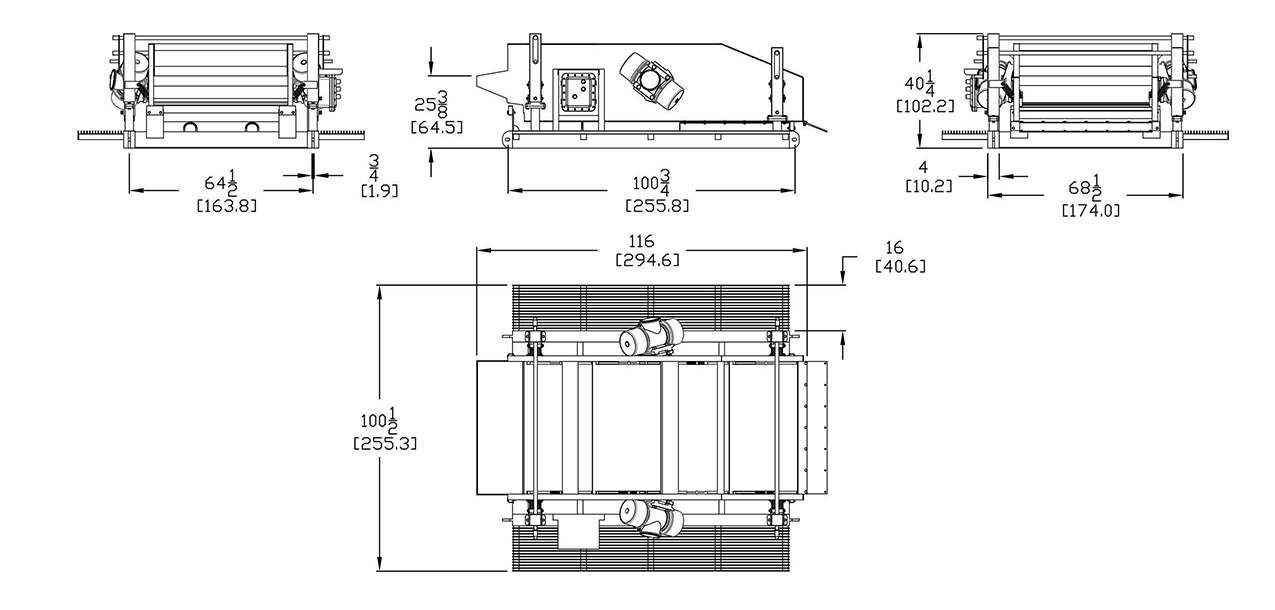

Orbital 3000 Drying Shaker With Walkways

DESCRIPTION

The ORBITAL® 3000 Drying Shaker with walkways is a four pannel shaker with extended feed section, mounted on an open frame base with personel walkways.

BENEFITS IN PROCESSING CUTTINGS

One advantage of the VFSI drying shaker is in processing cuttings. Competitor units have stationary sections which funnel cuttings to the shaker. These areas commonly plug up, must be claered, and can casue a mess. The VFSI Orbital 3000 Drying shaker features an extended section and are vibrated onto the screen eliminating cuttings holdup.

PERFORMANCE

The screen area of the Orbital 3000 Drying Shaker has 30 ft2 with 6 g’s of acceleration. The combination of screen surface area, high g’s, and screen motion make the Orbital 3000 one of the best performing machines in the industry. The Orbital 3000 shakers use progressive elliptical motion for extended screen life and excellent conveyance.

GRATED WALKWAYS

The grated walkways on each side of the unit keep the operator out of the mud and provide a convenient height to change screens and monitor performance.

FEATURES

ORBITAL® shakers have many beneficial features.

ACCELERATION: 6 g’s (standard) to 7.5 g’s (optional)

SCREEN AREA: 30 ft2 of screening area

MOTION: eliptical motion

SCREEN LIFE: ORBITAL® shakers have exceptional screen life

SEAL WELDED: Fully seal welded baskets.

LOW MAINTENANCE: Ultra low maintenance design

LOW NOISE: 70 db standing 3ft from discharge 10

ABRASION PERTECTION: two layers of powder coat

SCREEN SEALS: patent pending screen seals are as easy to change as a set of screens

VIBRATORS: vibrators are one of the most overbuilt electrically and mechanically in the industry

MANUFACTURING: Made in USA

Specifications

NAME: Orbital 3000 Sump Drying Shaker

SCREEN AREA: 30 ft2 [2.8 m2 ]

“G” FORCE: 6 g’s (standard), 7.5 g’s (optional)

MOTION: Progressive Eliptical

DIMENSION (LxWxH): 116×100-1/2×40-1/4in (295x255x102cm)

WEIGHT: 3200lb [1455 kg]

FEED HEIGHT: 25-3/8in [65cm] (standard) – adjustable

ADJUSTMENT ANGLE: 0 to 8 degrees

ANGLE CHANGE TYPE: hand crank (standard) or center wheel (optional)

SCREEN TYPE: pretension

SCREEN NUMBER: 4 screens

SCREEN SIZE: 48 x 24 in [112 x 61 cm]

MOTORS: Italvebras, 1200 or 1800 rpm, 50 or 60 hz

MOTOR TYPE: explosion roof

ELECTRICAL BOX TYPE: explosion roof