Products

Complete Solids Control offers high-performance centrifuges designed to efficiently remove ultra-fine solids from drilling fluids. Made with high-grade stainless steel for superior durability and corrosion resistance, our centrifuges optimize mud properties, reduce disposal volumes, and enhance overall drilling efficiency. Supported by skilled technicians, our equipment provides reliable, precise solids control to keep operations smooth, safe, and cost-effective.

Complete Solutions for Drilling Efficiency and Waste Reduction

At Complete Solids Control, we understand the unique challenges in drilling operations and are dedicated to providing solutions that tackle them head-on. Our range of advanced products, including centrifuges, drying shakers, and surface rentals, is designed to keep your operations smooth, efficient, and cost-effective.

Our Products, Your Solutions

At Complete Solids Control, our products are designed to solve the toughest challenges in drilling operations, enhancing efficiency and reducing waste every step of the way.

Centrifuges

How a Decanter Works

The centrifuge is fed through a stationary pipe inside a hollow shaft connected to the screw conveyor (scroll). The feed enters a compartment within the conveyor and is accelerated through feed slots into the bowl’s interior. Once inside, centrifugal forces accelerate the solids, which collect on the bowl’s inside diameter wall. Meanwhile, the liquid forms a concentric annulus and fills the bowl to the level of the effluent dam/weirs.

The screw conveyor, coupled to a gearbox, rotates slightly slower than the bowl. This slower rotation, combined with the helix angled toward the smaller diameter (conical end), conveys the solids along the bowl’s inside diameter to the solids discharge end.

The liquid flows around the screw conveyor and exits through the effluent dam/weirs located at the larger diameter (cylindrical end) of the bowl. Solids that do not settle on the bowl’s inside diameter (floaters) are carried out with the liquid through the effluent weirs.

Adjustable effluent dams/weirs control the liquid volume inside the bowl. The maximum volume (pool) creates an annulus diameter smaller than the solids discharge diameter, ensuring effective separation and discharge.

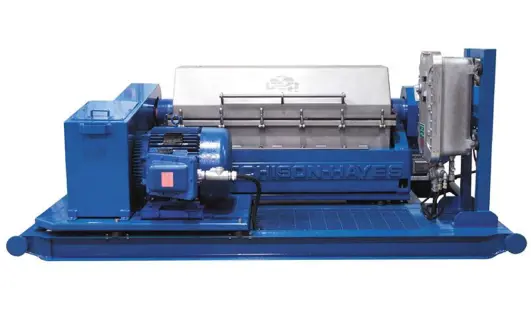

HH1448

Maximum Rated Capacity 225 GPM

Minimum temperature: 30F

Maximum temperature: 212F

Recommended throughput:

MUD weight 13 PPG: 30 GPM

MUD weight 11 PPG: 60 GPM

MUD weight 10 PPG: 100 GPM

Barite recovery RPM: <2250 RPM

Conveyor diffrential 42 RPM

G-force: 1000 G

Polishing RPM: 3250

Conveyor differential 61 RPM

G-force: 2100 G

Run up time: 5 minutes

Run down time: 15 minutes

Maximum RPM allowed: 4000 RPM

Bowl

Diameter: 14\”

Length: 48\”

Conical section: 10degree

Conveyor pitch:4\”

Gear Box

Ratio: 1:52

Torque: 22000 lbs

Shipping Data

Net weight: 4500 lbs

Gross weight: 5200 lbs

Volume: 128 cu. ft.

HH1448

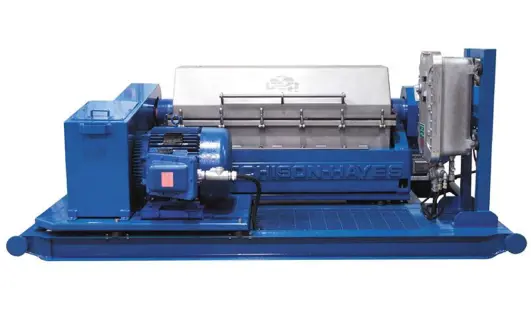

The HH 5500 Standard is a basic drive system configuration for a decanting centrifuge. This setup represents the most fundamental option among various available configurations. The centrifuge bowl is powered by a main drive motor, while the conveyor is driven via a planetary gearbox with a simple torque arm arrangement.

The torque arm acts as a torque-limiting device, safeguarding both the gearbox and the conveyor from mechanical overload. The conveyor speed is determined by reducing the bowl RPM according to the gearbox ratio.

Maximum Hydraulic Capacity 230 GPM

Minimum temperature: 30F

Maximum temperature: 212F

RPM standard step sheave: 2,000 & 3,050 RPM

Run up time: 8 minutes

Run down time: 20 minutes

Materials

Bowl: AISI 316

Conveyor body: AISI 316

Base: Cast iron

Cover/Case: SS 316

Paint: Epoxy

Conveyor tips: Tungsten Carbide

Solids discharge: Tungsten Carbide

Feed nozzles: Tungsten Carbide

Bowl

Diameter: 16\”

Length: 55\”

Conical section: 10°

Conveyor pitch: 4.25\”

Gear box

Ratio: 53:1

Torque: 36,000 lb-f/in.

Shipping Data

Net weight: 8,200 Lbs

Electrical Requirements

Main Motor: 60 HP

Full Load Amps: 72 (460V, 3ph., 60Hz)

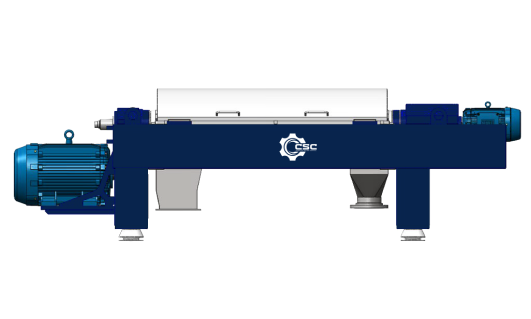

CSC18

Performance

Max Bowl Speed: 3,460 rpm

Rate Flow Capacity: 325 gpm

G-Force: 2246 G’s @ 3,000 rpm

Bowl

Diameter: 17.6” (447mm)

Length: 74.5” (1,892.3mm)

Beach Angle: 2.5° – 6° – 8.5°

Solids Discharge: 360°

SS2000

Performance

Max Bowl Speed: 2,700 rpm

Max Centrifugal Force: 3,050 gpm

Rate Flow Capacity:660 Gal/Min

Unweighted Drilling Mud:528 gpm

Bowl

Material: Stainless Steel

Rotating Assembly: 21\”x72\”/125 hp (533 x 1829 mm)

Weight: 16,300 lbs (7,400 kg)

Beach Angle: 5°

Solids Discharge: 90°

Drying Shakers

Complete Solids Control offers premium linear motion drying shakers to ensure a fast and efficient turnaround time on your fluid recovery process. Our linear motion drying shakers are multi-functional drilling fluid cleaners built to handle varying drilling fluid viscosities and remove solids from drilling fluid.

Complete Solids Control and waste management services offer THE complete solution for closed-loop, zero-discharge systems. Our goal is to reduce liquid waste haul-off. Our linear motion drying shaker, coupled with advanced fine screening, plays a significant role in the complete closed-loop package. We can install double or triple shaker systems as needed.

Orbital 3000 Drying Shaker With Walkways

DESCRIPTION

The ORBITAL® 3000 Drying Shaker with walkways is a four pannel shaker with extended feed section, mounted on an open frame base with personel walkways.

BENEFITS IN PROCESSING CUTTINGS

One advantage of the VFSI drying shaker is its ability to process cuttings efficiently. Competitor units feature stationary sections that funnel cuttings to the shaker. These areas are prone to clogging, require frequent clearing, and can cause a mess. The VFSI Orbital 3000 drying shaker, however, features an extended section that vibrates onto the screen, eliminating cuttings hold-up.

PERFORMANCE

The screen area of the Orbital 3000 Drying Shaker spans 30 ft² with 6 g’s of acceleration. The combination of screen surface area, high g’s, and screen motion makes the Orbital 3000 one of the best-performing machines in the industry. The Orbital 3000 shakers use progressive elliptical motion for extended screen life and excellent conveyance.

GRATED WALKWAYS

The grated walkways on each side of the unit keep the operator out of the mud and provide a convenient height to change screens and monitor performance.

FEATURES

ORBITAL® shakers have many beneficial features.

ACCELERATION: 6 g\’s (standard) to 7.5 g\’s (optional)

SCREEN AREA: 30 ft2 of screening area

MOTION: eliptical motion

SCREEN LIFE: ORBITAL® shakers have exceptional screen life

SEAL WELDED: Fully seal welded baskets.

LOW MAINTENANCE: Ultra low maintenance design

LOW NOISE: 70 db standing 3ft from discharge 10

ABRASION PERTECTION: two layers of powder coat

SCREEN SEALS: patent pending screen seals are as easy to change as a set of screens

VIBRATORS: vibrators are one of the most overbuilt electrically and mechanically in the industry

MANUFACTURING: Made in USA

Specifications

NAME: Orbital 3000 Sump Drying Shaker

SCREEN AREA: 30 ft2 [2.8 m2 ]

\”G\” FORCE: 6 g\’s (standard), 7.5 g\’s (optional)

MOTION: Progressive Eliptical

DIMENSION (LxWxH): 116×100-1/2×40-1/4in (295x255x102cm)

WEIGHT: 3200lb [1455 kg]

FEED HEIGHT: 25-3/8in [65cm] (standard) – adjustable

ADJUSTMENT ANGLE: 0 to 8 degrees

ANGLE CHANGE TYPE: hand crank (standard) or center wheel (optional)

SCREEN TYPE: pretension

SCREEN NUMBER: 4 screens

SCREEN SIZE: 48 x 24 in [112 x 61 cm]MOTORS: Italvebras, 1200 or 1800 rpm, 50 or 60 hz

MOTOR TYPE: explosion roof

ELECTRICAL BOX TYPE: explosion roof

Surface Rentals

Open Top Containment

Our shale bins come in 20′, 30′, and 40′ L sizes, and are designed to fit any and all rigs for drill cuttings and solids handling. Built with heavy-duty industrial steel, these bins are engineered to prevent damage, making Complete Solids Control bins some of the most robust containment bins in the industry.

Case 130 Excavator

Our CASE CX130D excavators provide greater fuel efficiency, more power, higher lifting capacities, and better controllability. In addition to the high precision and smooth control of our CASE Intelligent Hydraulic System, the CX130D features a new electronically controlled hydraulic pump, a larger control valve, and solenoid valves. Operation is a breeze for solids handling and is managed by a Complete Solids Control experienced excavator operator.